A Brief Explanation of Calibration Fixtures and Precision Voltage

In the manufacturing sector, a “fixture” usually refers to a device that holds a part or parts in a particular place or orientation while an operator performs a task. Think about a clamp that holds two pieces of wood together while someone drills a pilot hole and then drives a screw. We use specifically designed fixtures in manufacturing to ensure that all items that come off of a production line are uniform. As they pass through the process, they are each held in place by the same fixture, thus ensuring that that task was completed in the same way. For example, the angle of the volume antenna on every Etherwave Theremin is the same because they were all held in place by the same fixture during the installation of their volume antennas.

In this article, we will refer to “calibration fixtures.” Think of these as equivalent devices, but instead of physically holding parts in place for assembly, they generate electronic signals that we can use to calibrate the Control Voltage (CV) inputs on our instruments. Those signals are precise, steady voltages. Essentially, the calibration fixtures hold the CVs in place while an operator either adjusts variable resistors or uses a computer to send System Exclusive (SysEx) files that inform the firmware about what kind of CV is being applied.

A major reason we want to do this is to ensure a one-volt-per-octave response of the oscillators to the CV applied to their pitch inputs. This means that a change of 1V in CV will result in a change of one octave in pitch. For example, if 1V applied to an oscillator’s pitch control input produces a pitch of C4, then 2V will produce a C5. In order to do this precisely and uniformly across an entire production run of an instrument, we developed calibration fixtures that generate precise and steady voltage signals.

Ethervox

It started with the Ethervox Theremin. We developed a calibration fixture that included a precision voltage output for tuning the oscillators. By applying integer values of voltages (1.00V, 2.00V, 3.00V, etc.) to the pitch input jack and adjusting internal trim pots, we could tune the CV input to have a one-volt-per-octave response.

Taurus and Minitaur

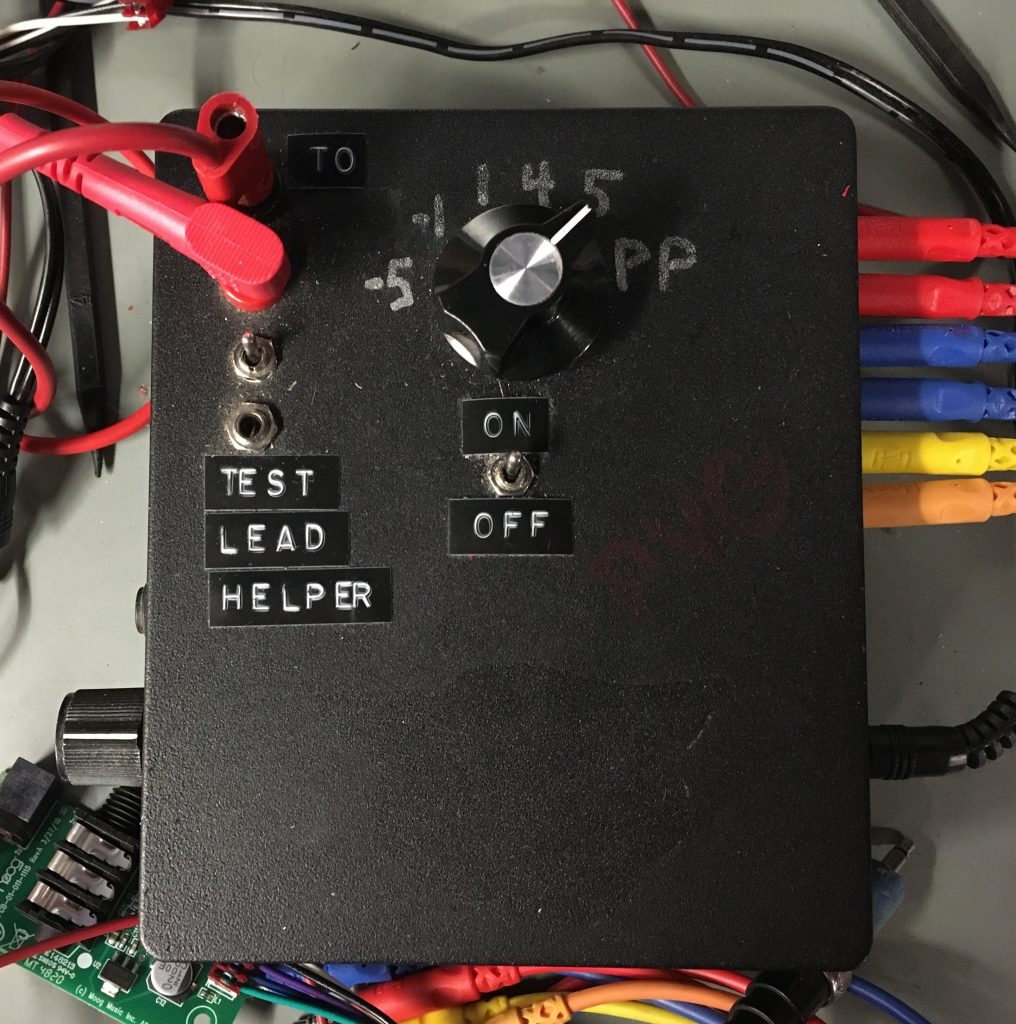

Taurus 3 introduced a new concept to the Moog synthesizer family: the digital CV input. This means we had to calibrate something in a way we had not before: by applying several precise voltages to an input jack and telling the firmware to recognize those voltages. Later, the Minitaur, a direct descendant of the Taurus 3, used a similar calibration fixture. We still use that box, pictured below, in the production of Minitaurs today.

Sub Phatty and Sub 37

This calibration fixture used a circuit build on a piece of breadboard with point-to-point soldering and panel mounted hardware. One could calibrate the +1V and +4V signals using multi-turn trim pots. We re-purposed this design for a calibration fixture that we used in the production of Sub Phattys and Sub 37s and added a variable resistor for testing the expression inputs without a pedal. The term “port-a-pot” comes from a modular-era accessory.

Mother-32

For Mother-32, we needed different voltage options for calibrating the digital tempo input. We designed a PCB for this iteration of the box, which included options for integer values of voltage ranging from -5V to 5V, although only -5V and 5V were utilized for Mother-32 production. Mother-32 does not have expression inputs, so the Porta-Pot was removed from this box. Since the PCB implemented Surface Mount Technology (SMT), we could fit it in a much smaller project box, which aligned with the compact design of the Mother-32 itself.

DFAM

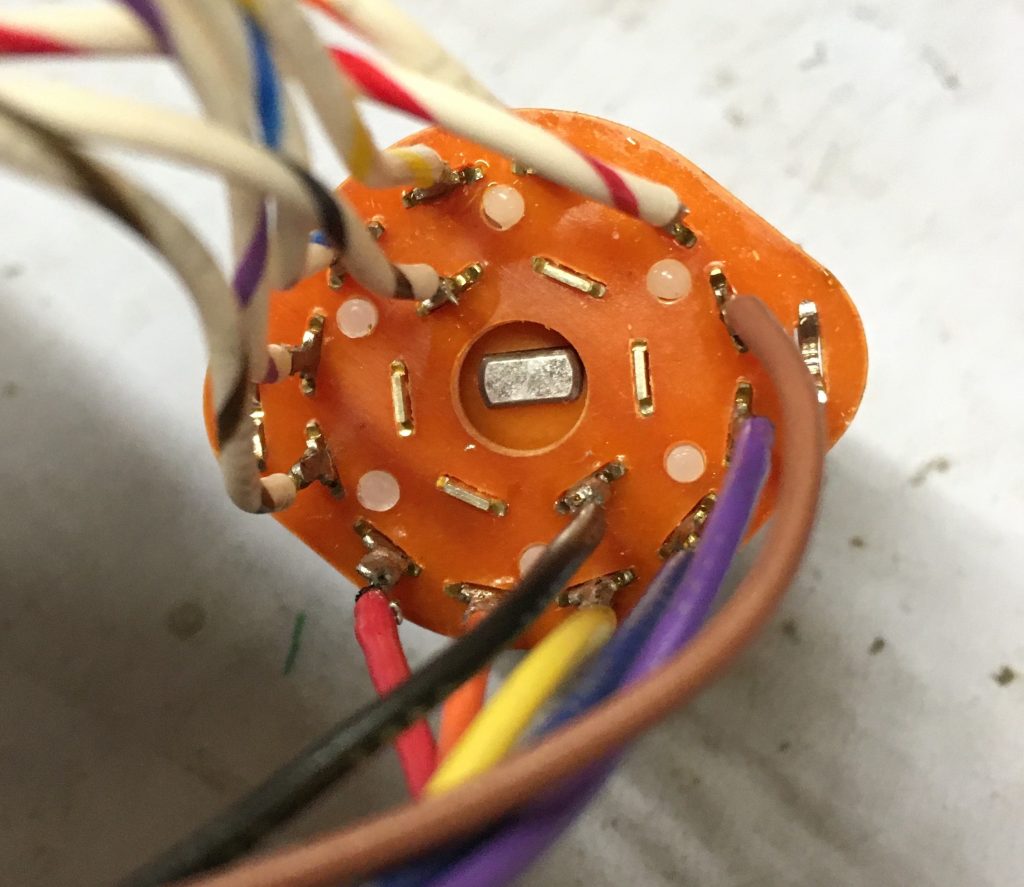

DFAM, the next 60HP instrument we put into production, is a fully analog instrument, so the precision voltage generator was not necessary for any digital inputs. However, the calibration fixtures had been so useful in other analog calibrations that we planned for using a similar box. DFAM needed different voltage values (–1V, +1V, +2V, and +5V). The PCB designed for the Mother-32 box had the options, so we simply wired a four-position rotary switch to different points on the PCB with a few more resistors populated.

Multi-use Fixtures

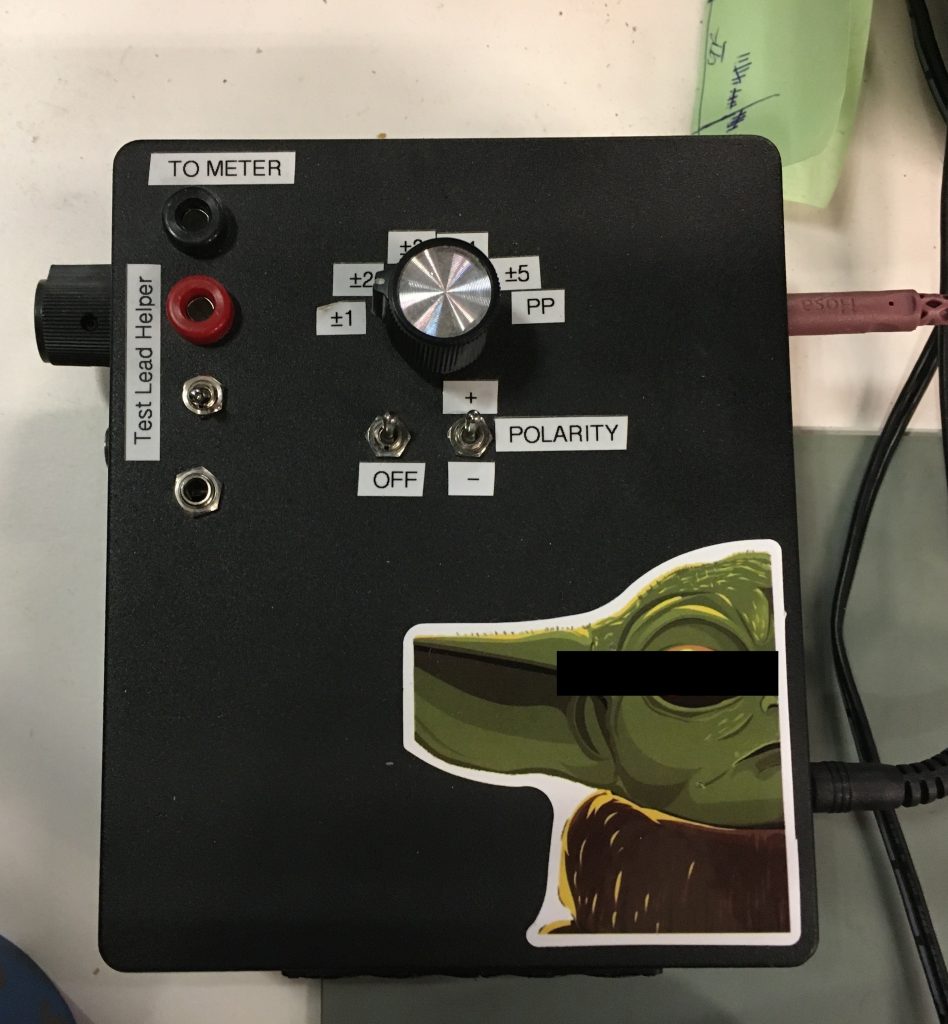

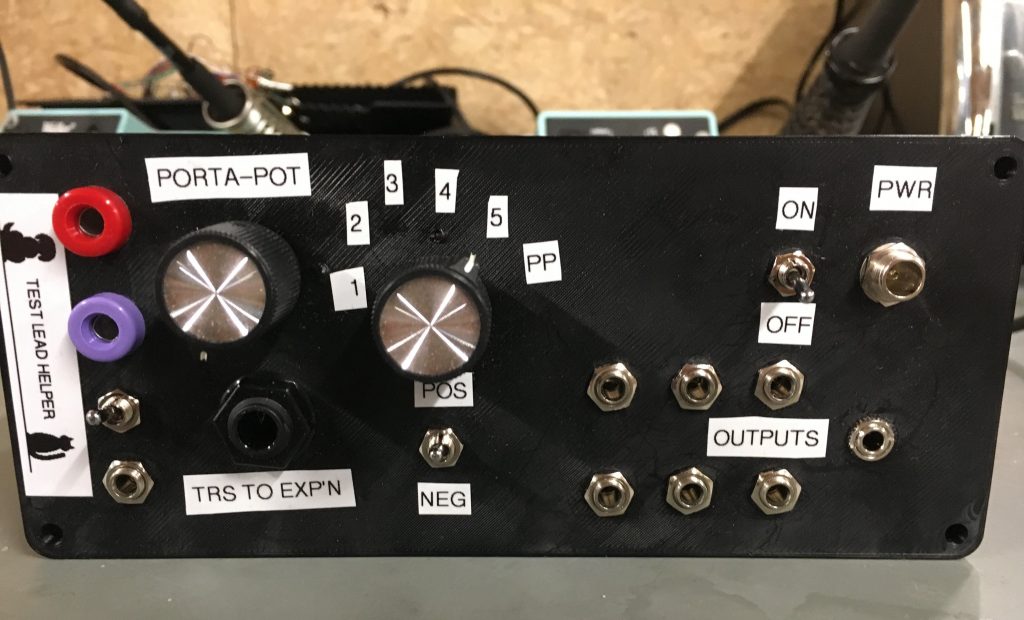

With Sub Phatty, Sub 37, Minitaur, Mother-32, and DFAM all in production, and with a new effort to standardize the production lines to make them more flexible, we wanted to combine the boxes into one that could do all the things we needed for any of the instruments’ calibrations. Pictured below, the first of these had limited voltage selection. Eventually, we replaced the four-position switch with a six-position switch and chose the five voltages we would use the most (-5V, -1V, +1V, +4V, and +5V). The sixth position selects the signal from the Porta-Pot circuit that we added to the box for the Sub Phatty and Sub 37 expression inputs.

Multiple Outputs

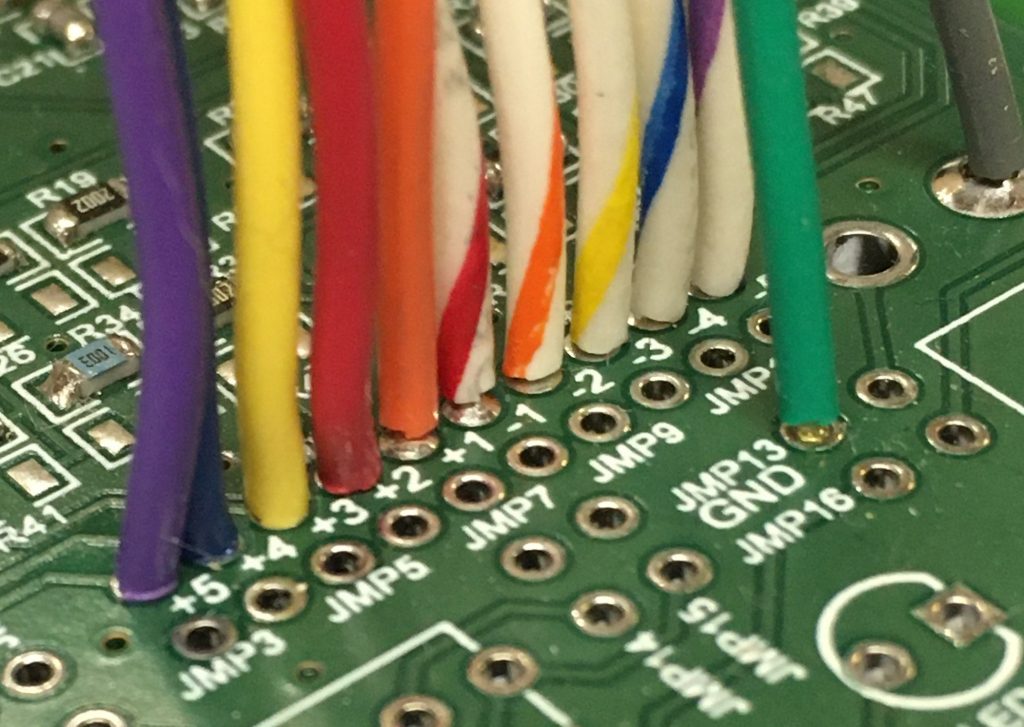

Subharmonicon increased the number of digital inputs that needed calibration from one to six. In order to avoid having to calibrate each one in turn, we multiplied the output on the calibration fixture and provided an extra output for monitoring. That way, we could apply the same voltage to all the inputs and send a System Exclusive (SysEx) file to calibrate all of them at once. The panel knob calibration is performed at the same time with the same SysEx files.

Test Lead Helper

Next, we included a feature that we called a Test Lead Helper. This is a passive part of the fixture that allows a Digital Multi-Meter (DMM) operator to easily switch between using a probe and a 3.5mm patch cable. It consists of two banana plugs, a toggle switch and a 3.5mm jack. One banana plug can be connected to a DMM while the switch selects whether the signal from the other banana plug or the 3.5mm jack is sent to the DMM.

All the Voltages

After deliberating on which five voltage values to use, we decided to make all of them an option. The six-position switches we were using had two poles, so we wired the negative voltage values to one side of the switch (striped wires in the picture below) and the positive values (solid colors) to the other side. Then, we added a toggle switch between the selector switch and the bypass switch that toggles between positive and negative values.

3D-printed Enclosures

Around the time Subharmonicon was hitting the production floor, we acquired a 3D printer for prototyping and production fixtures. As the precision voltage generators evolved, we kept adding holes that needed to be drilled into the off-the-shelf project boxes we were using for housing. The addition of the six holes for the multiplied outputs made the drilling process a little too time consuming and labor intensive, so we started printing enclosures out of ESD-safe PETG plastic. Eventually, we started saving time and effort on labeling by printing the control indicators directly into the panel. The 3D printing process also provided some additional opportunity for creativity in design.

What’s Next?

This is the current state of the Moog multi-purpose precision voltage generator calibration fixture. What’s next in their development is still up in the air. With new instruments in development, we will most likely come across some new need for the PVG Box. The PVG Box has traditionally been a project that engineers can use to learn or develop skills (soldering, 3D-printing, circuit design), and the CNC machine we just added to our prototyping equipment is thirsty for some experimentation. Maybe the next Box will be custom-cut steel. The future is undefined and malleable.